Maintenance Checklist for Hospital Gas Manifold Systems: Avoiding Downtime & Leak Risks

Hospital Gas Manifold Maintenance

A hospital’s medical gas manifold system is one of the most critical components of its infrastructure. These systems deliver life-supporting gases such as oxygen, nitrous oxide, medical air, and vacuum — ensuring continuous patient care in ICUs, OTs, emergency units, and general wards.

Any malfunction, leak, or downtime can lead to serious safety risks, treatment delays, and even life-threatening situations.

That’s why regular and systematic maintenance is essential.

This blog provides a complete maintenance checklist to help hospitals prevent leaks, improve efficiency, and ensure 24×7 uninterrupted gas supply.

Why Maintenance Matters in Medical Gas Manifold Systems

✔ Prevents leakage of life-support gases

✔ Ensures consistent pressure and supply to all departments

✔ Reduces risk of fire hazards and oxygen-rich atmosphere

✔ Extends equipment lifespan

✔ Helps in NABH & other compliance audits

✔ Minimizes costly emergency repairs

✔ Guarantees patient safety

A well-maintained manifold system means zero downtime and maximum reliability.

Maintenance Checklist for Medical Gas Manifolds

1. Inspect the Cylinder Bank & Manifold Connections

- Check for loose fittings and ensure all connectors are tightened properly.

- Inspect cylinder valves, flexible hoses, and yoke connectors for wear and tear.

- Ensure cylinder alignment and secure positioning to prevent tipping.

- Verify the condition of non-return valves and pressure relief devices.

Frequency: Daily visual inspection + monthly detailed check.

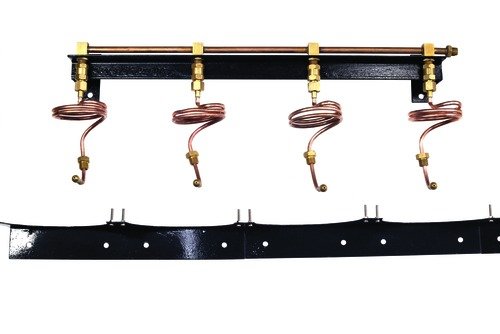

2. Check for Gas Leaks

- Apply leak-detection solution around joints, clamps, diaphragm valves, and pressure regulators.

- Listen for hissing noises indicating small leaks.

- Inspect the copper pipeline and flexible hoses for cracks or corrosion.

Never use open flames for leak testing.

Frequency: Weekly + urgently after cylinder replacement.

3. Monitor Pressure Regulators & Gauges

- Ensure the primary and secondary pressure regulators maintain correct output pressure.

- Check for fluctuations in supply pressure.

- Calibrate gauges periodically to maintain accuracy.

- Replace damaged or fogged gauge displays.

Frequency: Monthly calibration check.

4. Inspect the Automatic Changeover System

The changeover system switches gas supply from empty cylinders to full ones automatically.

Checklist:

- Verify smooth functioning without manual intervention.

- Test both sides (left & right banks) to ensure balanced operation.

- Clean sensors and test solenoid valves.

- Check alarm panel integration for low/high pressure alerts.

Frequency: Monthly.

5. Ensure Proper Alarm System Functioning

Alarm panels warn staff about supply issues before they turn into emergencies.

Check for:

- High/low-pressure alarms

- Empty cylinder bank signal

- Power failure alarm

- Fault indicators

Make sure all alarms are audible and visible.

Test alarm communication with the central monitoring system.

Frequency: Monthly + after maintenance work.

6. Monitor Oxygen & Other Gas Purity

Gas purity can affect patient health and medical equipment efficiency.

Maintenance actions:

- Test purity using approved analyzers.

- Check for contamination, odor, or discoloration of gas outlet points.

Frequency: Quarterly or as per hospital protocols.

7. Clean Filters & Replace When Needed

Dust or debris in the system can affect pressure regulation and flow.

Checklist:

- Clean inlet filters

- Inspect particulate filters

- Replace activated carbon filters if present

Frequency: Every 3–6 months.

8. Inspect Copper Pipeline & Valves

- Look for corrosion, bends, or improper support clamps.

- Check isolation valves for smooth rotation.

- Lubricate where required (only with approved medical-grade substances).

Frequency: 6-monthly.

9. Verify Electrical Components & Backup Power

Many manifold systems operate with electronic sensors and alarm panels.

Checklist:

- Check wiring integrity

- Test backup batteries

- Inspect control panel for moisture or dust

- Ensure grounding is intact

Frequency: Quarterly.

10. Maintain a Logbook & Service Record

Every inspection should be documented:

✔ Date of inspection

✔ Observations

✔ Issues found

✔ Parts replaced

✔ Technician’s name

A logbook helps with audit compliance, troubleshooting, and performance tracking.

Best Practices to Avoid Downtime & Leak Risks

- Always use certified technicians for installation and service.

- Replace flexible hoses every 3–5 years.

- Use only BIS/ISO-approved cylinders and connectors.

- Train staff on safe cylinder handling.

- Conduct annual preventive maintenance with a qualified service provider.

- Keep spare parts (regulators, gauges, hoses) in stock for emergencies.

Conclusion

Medical gas manifold systems are the backbone of any hospital’s life support infrastructure.

With proper maintenance, hospitals can ensure:

✨ Zero leakage

✨ Zero downtime

✨ Maximum safety

✨ Extended system life

✨ Reliable oxygen and gas supply

A consistent and well-documented maintenance routine is essential for safe and uninterrupted patient care.